5T Manual Decolier For Free

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 500mm

Structure: welded by the steel plates and profiled bar. The shrink and expand of coil is automatic , Drive by Hydralic power.

Design Idea: We have enhanced the thickness of the roller and the diameter of the shaft to produce thicker and larger-sized Purlins. The maximum thickness of purlin is 4mm and the maximum size is 400mm. The heavy-duty CZ purlin machine has a very stable advantage for the production of large-size Purlins.

Standard sepcification: Width from 100-400 mm , Thickness from 1.5-4mm , other specail size we can also customized.

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 500mm

Structure: welded by the steel plates and profiled bar. The shrink and expand of coil is automatic , Drive by Hydralic power.

There is an electric button here, which can automatically adjust the feeding width Leveling rollers: 3 up 4 down

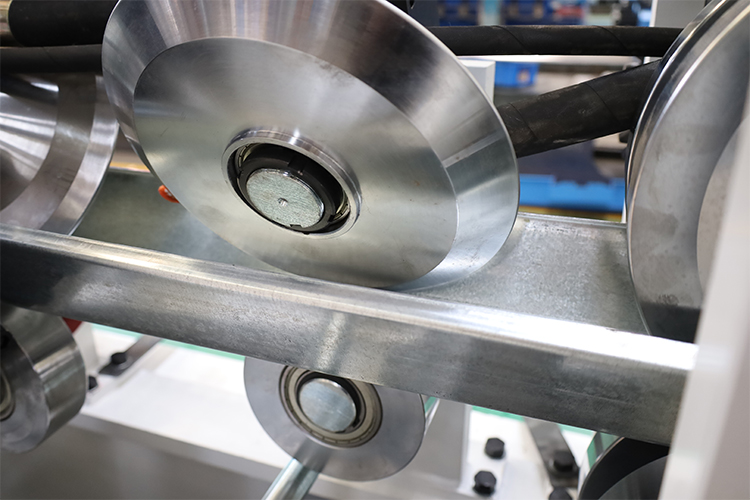

Roller material: Cr15

Roller diameter: 75mm

Feeding width adjustment: automatic by button Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate

Rollers material: Cr12

CNC processing heat treatment to HRC: 58-60

Finish Turning Roller stations: 21 rows , 12 unit roller stations for C and Z changing.

Shaft material: 40 Cr CNC processing HRC 28-32 ,finish turning and electroplate Drive

By Heavy Duty Chains: 1.5 inch

Material of blade: Cr12

Mov Quench Treatment Length measuring: automatic encoder measuring,Tolerance of length is 3000mm+- 1.0mm You can manually adjust the cutter to cut different sizes of c/z purlin. You do not need to change new blade and this cutter is easy to operate.

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

● Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Why Choose To Cooperate With Hener?

COLD ROLL FORM SOLUTION

① Our mission is to provide our customers with the very best quality metal rolling automation solutions and after-sales service.

② Our cold roll form machine offers a wide range of coil feeding equipment, including Decoiler, Steel Straightener, Coil Feeder as well as numerous rolling automation machines like color steel roofing sheet machines, cz purline machines, roof sheet manufacturing machine and others.

③ Metal coil processing can be carried out more efficiently and more accurately for betterreliability, less waste, and improved productivity.

COLD ROLL FORM RESEARCH

① Hener Roll Form Machine Equipment commits to provide customized coil processing solution according to each customer' sspecific metalworking process.

② With experienced technical team and continuous researching investment, Hener is capable to offer coil handling solutions that meet higher international standards.

QUALITY CONTROL

① From spare parts preparation to equipment assembly, our cold roll form machine can offer real-time manufacturing update for our vilued customers.

② From raw material control, spare parts inspection and machine assembly, Hener cold roll form machine factory implements a strict quality control process.

③ We commit to offer coil handling equipment with working stability, operation safety, and achieve precision straightening and feeding performance. All work are just for making sure all the products of machines are qualified.

Feedback of Philippine customer products

View More

Cutting-edge technology for maximum safety and minimum investment

Get In Touch

Hengna always hopes to win your long-term trust and support with professional services, high-quality products and competitive prices.